Suddenly having an opportunity to enjoy 80% savings in packaging material costs and 15% savings in transport cost doesn’t sound possible, but it is if you consider changing from standard pallets to Slip Sheets handling = palletless handling. Anyone who has made this change, will not return to the old way.

Actually, I wrote this article already some time ago, but now in 2023 I can update and confirm you that the demand of Slip Sheets is steadily growing as many companies have experienced its advantages. Especially this past year has been challenging for all of us, not only because of the pandemic health effects and restrictions, but also how it has impacted the packaging world in terms of increasing cost of material and freight as well as their availability.

The reduction of cost that Slip Sheets can provide you is now more important than ever!

By clicking the button below, and going to page 7, you see transport savings have a very important role especially when talking about overseas shipments or other long distances.

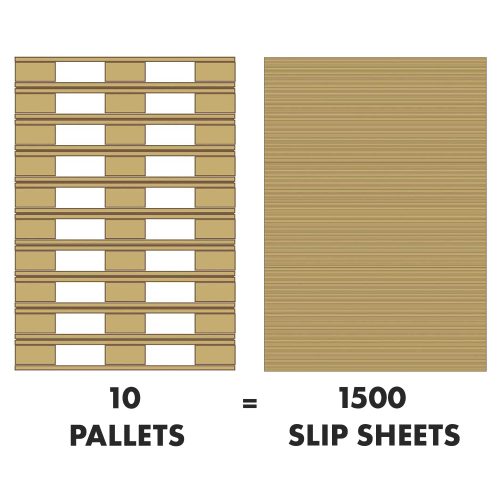

It really makes sense to take this new step, not only because of the huge savings, but also due to other great advantages that can be enjoyed. Think about having 1,500 Slip Sheets in the same space in your warehouse where you could fit only 10 standard pallets before. You will be saving money and space and getting rid of all those heavy pallets that were not so user-friendly (splinters, repairs, heavy-to-handle, etc.). Think about how much more goods you will be able to load, not only due to the volume, but also due to the light weight of the sheets compared to heavy pallets!

With Slip Sheets, you can gain even 8 m3 more space in a 40-foot container, which allows you to transport an extra amount of your products.

Nobody wants to transport pallets, the aim is to transport your goods.

It sounds like a dream come true! Think about presenting this opportunity to your colleagues and superiors!

So what is Slip Sheet exactly? It is a strong laminated kraftliner sheet which can replace wooden or other standard pallets. The sheet is only about 1 mm thick, but even so can still transport heavy loads weighing more than a tonne. With a Push Pull attachment, which can be fitted to any fork lift in less than a minute, you can easily handle your “new pallets”. It is said that in the United States Slip Sheets are as common as Euro-pallets in Europe. Every day more and more companies are introducing Slip Sheets when shipping goods in containers or in trucks in/from Europe, Asia … everywhere in the world.

Companies who use Slip Sheets can be found in many different sectors. Main sectors are food, beverage and consumer goods (electronics, kitchenware etc.) companies who are exporting or shipping to longer distances. Slip Sheets are also used for deliveries from raw material suppliers to their customers, where deliveries are often constant. Intercorporate shipments from production plant to distribution centers can be well optimized by using Slip Sheets.

It is important to realize that before loading the container you can still use standard pallets in your warehouse, which makes the change easy. Only when you are ready to ship the goods, you leave the traditional pallets behind and use them over and over again. The same can happen in the destination if customer prefers to handle standard pallets internally. The main target, in this part of your logistic chain, is to have the long distance transport volume maximized per shipment and as effective as possible so that you can load more and save money in the shipping operation.

In overseas shipments the freight cost has a significant role in the final cost. With Slip Sheets you can optimize your shipments by loading more goods per container. This can result in huge savings of even 15% from your previous cost. This can be the deciding factor for closing a new business or keeping your old business in times when freight costs are getting higher.

Wooden packaging is becoming more and more expensive, and their availability is occasionally insecure. When you compare standard pallet prices with Slip Sheet unit cost, there is a huge difference, even 80%, and if you compare with plastic pallet prices the difference is naturally even higher. It is worth while checking what kind of savings your company could have with this change. If you are looking for economical, sustainable, 100% recyclable, hygienic, safe, light-weight and user friendly pallets, then Slip Sheets are an excellent choice.

Another positive fact is that you don’t need to heat-treat Slip Sheets according to Phytosanitary Regulations (ISPM 15) as you need to do with wooden pallets on intercontinental shipments.

Choosing a sustainable 100% recyclable transport packaging material is your contribution to the environment as a responsible company. We all need to reduce material use and the burden of Mother Nature. We need to replace materials so that we can participate in the important mission of reducing our carbon footprint in all our actions.

Both your Sustainability Manager and Sourcing responsible will greet this alternative with open arms!

Last but not least, it’s time to talk about raw material. The highest-quality Slip Sheets are made from strong virgin kraftliner with long fibre structure. Make sure that you choose the right supplier with the highest standards of quality and you will have the best strength, tear and humidity resistance for your exact needs.

Eltete TPM has been the pioneer in introducing Slip Sheets to Europe.

With efficient and high-capacity global production and sales network we can supply customers to any location in the word.

If you are looking for economical, hygienic, safe, light-weight and user friendly pallets, then Slip Sheet is an excellent sustainable choice for your company.

For more information, contact: