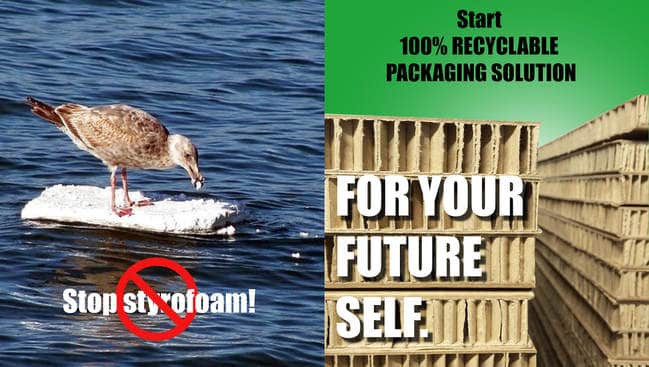

You know that package of your refrigerator, air conditioner, oven, etc, protected with EPS against transport damage? Have you experience the moment when you unpack and it breaks down into tiny pieces sticking to your house, to your skin like a plague? These tiny pieces still has all the chemicals and toxins that comprise the original product. Now image this ending up in our eco-system, in our oceans…

EPS is recyclable (Really?), disposable (to where?)

First of all, „Styrofoam“ (many might know it by this term) is actually just a brand name. :OOO Yep. The white product is called expanded polystyrene (EPS).

EPS has in its composition 98% of air and 2% of plastic. This means that when melted, the final volume of it drops to 10% of what was collected. For this reason, most cooperatives and companies in the recycling industry do not even accept donations, and much less are willing to collect it, since, due to its low density, it occupies a lot of volume, which makes it expensive to transport and, consequently, to be recycled, requiring very large quantities to make the process economically viable as a whole.

So, answering the question, when there is a huge amount of EPS material and no viable way of getting rid of it, here is what happens to all of it produced around the world:

- In the garbage, which will take at least 500 years to decompose.

- In landfills, which will take too much space and saturate waste areas more quickly, requiring large public investments in the construction of new landfills.

- If incinerated, EPS releases carbon dioxide, thus contributing to air pollution and global warming.

- In rivers, seas, oceans ingested by all kind of marine animals and organisms – the pieces of EPS will be quickly colonized by a thin layer of microbes, which releases chemicals that make plastic and „styrofoam“ smell and taste food for animals.

Is there an alternative to keep my goods safe?

Yes! Honeycomb board.

Combined with other recyclable solutions made out of carton, such as edgeboards, it gives you a complete excellent sustainable packaging, giving a good image to your company, helping the preservation of environment and bringing savings to your logistics chain.

Honeycomb board is lightweight but with a strong structure. It has good cushioning as well as insulation effect, and an excellent shock absorbing properties making it ideal for storing and transporting from fragile to heavy products. It can be die cut, shaped and it is 100% recyclable!

Unlike what happens with EPS, its recycling is easy and effective. The reason for this (yeeeees, I will mention again because it is a incredible process) is the increased adoption of forest management practices because for every tree harvested in a managed forest, several more are replanted or naturally regenerated in its place.

At the manufacturing level, what isn’t used in actual paper production is transformed into energy that fuels the process. Just think, all of this paper is being given a new lease on life and not going into the landfills – which are already brimming – around the world.

We are what we choose!

So, if there is an alternative good enough, actually, BETTER, economical, social and environmental speaking,

the usage of EPS to protect and transport goods should not be an option!

EPS is responsible for a tremendous portion of worldwide waste, a material that kills our animals, poisons our environment and dangerously compromises our health. Is this what your company chooses?

WE ARE WHAT WE CHOOSE.

CHOOSE OUR PLANET.

Industries: Go green!

Many companies from different sectors (food, white goods, electronics, etc) are banning the use of EPS.

End customers are complaining its presence in packages.

The industries that produces it should consider invest in a local manufacture of honeycomb board in order to eliminate this product and its hidden threats from the face of earth.

Eltete, besides selling over decades sustainable transport packaging solutions, also design, develop and manufacture the machinery responsible for its production.

Ask us!

Honeycomb machinery and Technology: Shanghai Eltete Packaging Technology Co. Ltd. It has been since 15 years back one of the leading machine and technology supplier of Honeycomb machines and equipment. See www.eltete.com.cn and www.duromek.com

Say no to styrofoam!